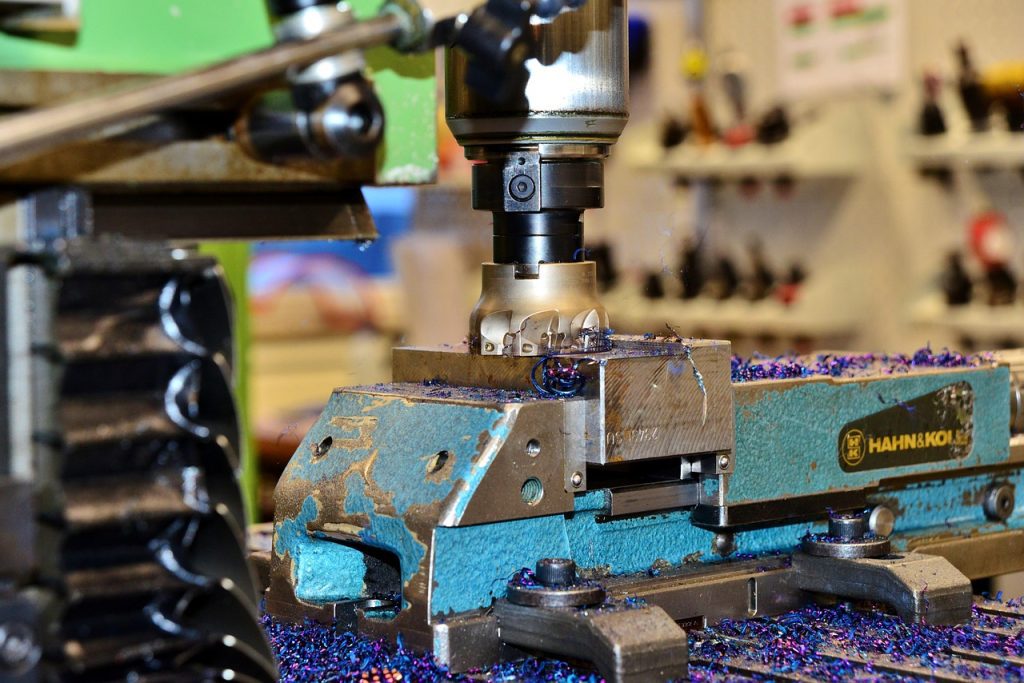

Job shops face unique challenges when it comes to keeping their machines productive throughout the workday. Unlike high-volume manufacturers that run the same parts repeatedly, job shops constantly shift between different projects with varying requirements and specifications.

This variety creates numerous opportunities for machines to sit idle between jobs, during setup changes, or while waiting for materials and programming. Understanding how to minimize these gaps in production can transform a shop’s output capacity without requiring major capital expenditures or facility expansions. The strategies that work best often involve rethinking existing processes and identifying where small improvements can accumulate into significant gains.

Standardizing Workholding Systems

Implementing consistent workholding approaches across similar part families reduces the variation in setup procedures. When operators use the same vise types, jaw configurations, or clamping methods repeatedly, they develop muscle memory and speed.

Standardization also allows shops to prepare fixtures while machines are running, enabling quick swaps between jobs. The reduced cognitive load on operators means fewer mistakes during setup, which prevents scrapped parts and time-consuming corrections.

Programming During Machine Runtime

Writing and verifying CNC programs while machines are cutting other jobs prevents idle time between production runs. Many shops dedicate separate computers for programming work so that operators can prepare the next job without interrupting current operations.

Simulation software helps verify programs before they reach the machine floor, catching potential errors that would otherwise cause expensive crashes or rework. This parallel workflow means machines can transition immediately from one completed job to the next without waiting for program creation.

Automated Pallet Loading Systems

A CNC pallet loader automatically exchanges workpieces or complete fixtures while the machine continues operating on other parts. These systems typically hold multiple pallets that can be loaded and inspected during machine runtime, then swapped in during brief exchange cycles.

Companies specializing in factory automation equipment offer these systems that focus specifically on pallet and fixture automation. Distributors of machine tool accessories also carry compatible pallet systems that integrate with various CNC machine models.

Tool Life Management Practices

Monitoring and replacing cutting tools before they fail prevents unexpected downtime and quality issues that stop production. Worn tools produce poor surface finishes and dimensional errors that require parts to be scrapped or reworked.

Systematic tool replacement based on usage tracking maintains consistent quality and prevents the machine from sitting idle while operators diagnose cutting problems. Fresh tools also enable more aggressive cutting parameters that can reduce cycle times for remaining tool life.

Queue Management and Job Sequencing

The order in which jobs are scheduled affects how quickly machines can transition between them and how often they sit waiting for materials or instructions. Grouping similar parts together minimizes the degree of change required between setups, allowing faster transitions.

Understanding which jobs share tooling, fixtures, or material requirements helps create efficient production sequences. Poor sequencing results in machines waiting for setups that could have been simplified through better planning.

Preventive Maintenance Scheduling

Regular maintenance activities keep machines running reliably and prevent unexpected breakdowns that halt production entirely. Scheduled maintenance can be planned during slower periods or coordinated with other necessary downtime, like tool changes or fixture modifications.

Machines that break down unpredictably create cascading delays as jobs get rerouted to other equipment or put on hold entirely. Well-maintained equipment also holds tolerances better, reducing quality-related stoppages and rework.

Bar Feeders and Stock Loading Equipment

Bar feeders attach to turning centers and automatically advance raw material stock as parts are completed, eliminating manual loading cycles. These devices allow lathes to run unattended for extended periods, particularly during night shifts or weekends when operators may not be present.

Equipment manufacturers produce bar feeding systems compatible with various lathe models and bar sizes. Industrial machinery dealers and turning center manufacturers often partner with or recommend specific bar feeder suppliers for their equipment.

Operator Skill Development

Well-trained operators can identify and resolve minor issues quickly rather than stopping production to wait for specialized help. Understanding machine capabilities allows operators to optimize feeds and speeds within programs, potentially reducing cycle times.

Skilled machinists also catch developing problems early, before they cause major breakdowns or quality failures. Cross-training operators on multiple machines provides flexibility when workload distribution becomes uneven across the shop floor.

Real-Time Production Monitoring

Digital monitoring systems track machine status throughout the day, revealing patterns in downtime causes and durations. This visibility helps identify which machines, shifts, or job types create the most significant utilization challenges.

Understanding actual performance patterns allows management to focus improvement efforts where they will have the greatest impact. Without measurement, shops often make assumptions about utilization problems that don’t reflect actual bottlenecks in their specific operations.

Improving machine utilization in a job shop environment requires attention to multiple aspects of daily operations rather than any single dramatic change. Each percentage point gained in utilization translates directly to increased production capacity from existing equipment.

The most successful shops approach utilization as an ongoing focus rather than a one-time project, continuously identifying new opportunities to reduce non-productive time. By examining setup procedures, operator workflows, automation opportunities, and maintenance practices together, job shops can find their own path to higher productivity based on their specific circumstances and constraints.