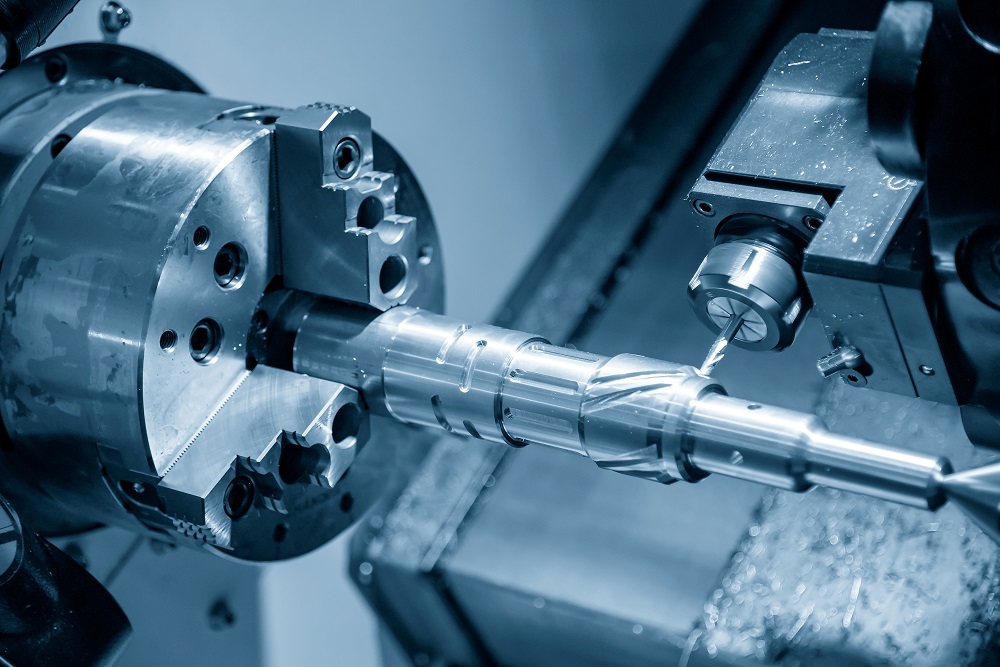

Industrial machines rely heavily on their spindles to deliver precision, speed, and consistent performance. Over time, wear and tear can reduce spindle efficiency and place stress on other machine components. Professional spindle repair focuses on restoring these critical parts before damage spreads or causes unexpected downtime.

Rather than waiting for total failure, timely repair helps machines operate within proper tolerances for longer periods. This approach supports both productivity and long-term equipment value. Understanding how professional spindle repair works can help businesses make smarter maintenance decisions. Below are the key ways this service contributes to extending machine lifespan.

Restoring Precision and Alignment

Professional spindle repair plays a vital role in restoring the original precision of a machine. As spindles wear, even minor misalignment can lead to vibration, inconsistent cuts, and reduced product quality. Skilled technicians carefully inspect bearings, shafts, and housings to identify hidden issues.

By correcting alignment problems, the spindle can rotate smoothly and evenly once again. This reduces unnecessary strain on motors and connected components. Proper alignment also helps machines maintain tighter tolerances during operation. Over time, this precision prevents accelerated wear and supports longer machine life.

Preventing Costly Secondary Damage

A worn or damaged spindle can affect far more than just one component. When left unaddressed, spindle issues often place extra load on belts, bearings, and drive systems. Professional repair helps stop this chain reaction before it escalates into major mechanical failure. Technicians replace or refurbish damaged parts to ensure balanced operation. This proactive approach minimizes the risk of breakdowns that could impact the entire machine.

In some cases, companies turn to service providers such as Anderson spindle repair services when diagnosing complex spindle-related issues. They help identify underlying problems that may not be visible during routine inspections and provide practical recommendations based on real-world repair experience. This additional insight can support more informed maintenance decisions and help prevent recurring spindle failures.

Improving Operational Efficiency Over Time

Machines with properly repaired spindles tend to operate more efficiently on a daily basis. Reduced vibration allows for smoother cutting and more stable speeds during production. This consistency lowers energy consumption and improves overall machine responsiveness. Operators also benefit from fewer interruptions and adjustments during normal use.

Over time, steady performance reduces fatigue on mechanical components. Efficient operation makes it easier to maintain predictable maintenance schedules. As a result, the machine remains reliable and productive for a longer period.

Supporting Long-Term Maintenance Strategies

Professional spindle repair fits naturally into a long-term maintenance plan. Rather than reacting to sudden failures, businesses can schedule inspections and repairs based on usage patterns. This approach allows maintenance teams to track spindle condition and performance trends.

Repaired spindles often perform closer to original specifications, making maintenance planning more accurate. Consistent upkeep also extends the service intervals of related components. A structured repair strategy reduces emergency downtime and unexpected costs. Ultimately, this proactive mindset helps maximize the lifespan of both the spindle and the machine as a whole.

Conclusion

Extending machine lifespan requires more than routine cleaning and basic upkeep alone. Professional spindle repair addresses one of the most critical and heavily used components in industrial equipment. By restoring precision, preventing secondary damage, and improving overall efficiency, repair services help machines age more gracefully under demanding workloads. This approach supports stable production, consistent output quality, and more predictable maintenance costs over time.

It also allows businesses to delay expensive machine replacements without sacrificing performance or reliability. Over time, repaired spindles contribute to safer, smoother, and more dependable operations across the production floor. Investing in professional spindle repair is a practical and forward-thinking step toward long-term equipment sustainability.